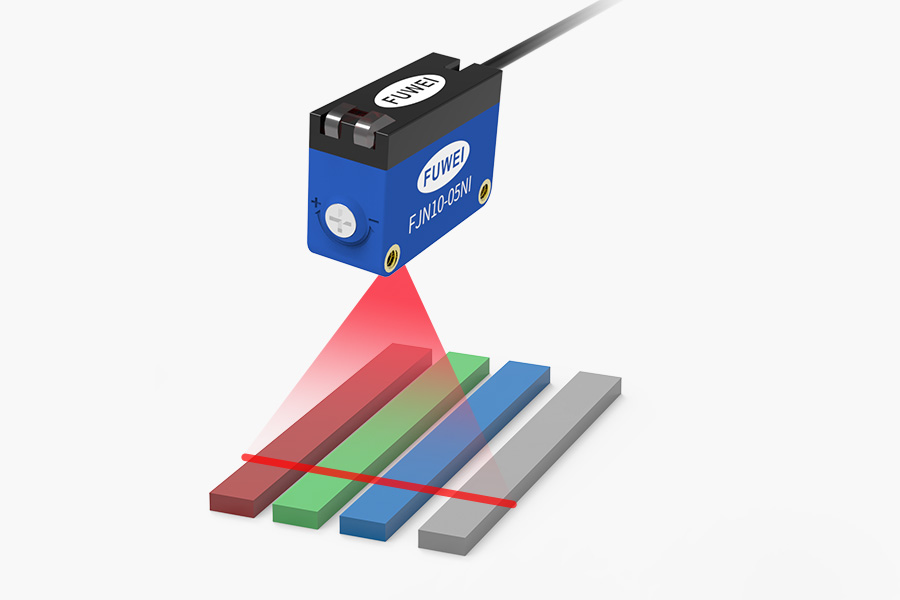

In the field of industrial automation, accurate detection is the core link to ensure production efficiency and product quality. In the face of complex and changing industrial scenarios, traditional sensors often affect production efficiency due to environmental interference, detection of blind spots or lack of adaptability. Relying on its profound R&D strength, Fuwei Electronics has launched the FJN10 series of square-shaped background suppression laser sensors, which redefine the new standard of industrial detection with high performance, high stability and strong adaptability.

Core Advantage: Responding to Complex Challenges with Technological Breakthroughs

1. Accurate detection without fear of color differences

FJN10 series equipped with 650nm red laser light source, combined with the diffuse reflection detection principle and advanced BGS (background suppression) function, can effectively filter the interference of ambient light, and accurately identify objects of different colors and materials. Whether it is dark-colored metal parts or light-colored plastic parts, it can achieve stable detection, avoiding the problem of misjudgment caused by the traditional sensors due to chromatic aberration, which is especially suitable for the sorting of multi-colored parts in automobile manufacturing, high-precision positioning in CNC machining and other scenarios.

2. Ultra-short response + intelligent adjustment, both efficiency and flexibility

The response time of this series of sensors is less than 1ms, which can capture the instantaneous state of high-speed moving objects and meet the stringent requirements of rapid sorting in mechanical equipment and dynamic monitoring of assembly lines. At the same time, it is equipped with a multi-turn potentiometer knob, which supports fine adjustment of the detection distance within a range of 30cm, easily adapting to the concave-convex surfaces, hollow structures and other complex workpieces, providing a flexible solution for the detection of shaped products in the 3C electronics, precision mold and other industries.

3. Anti-interference design, adapt to harsh environments

FJN10 series adopts IP65 protection level design, excellent dustproof and waterproof performance, and can be stably operated in oil, dust, humidity and other harsh working conditions. Combined with the excellent optical path design, the detection blind spot is extremely small, even when facing a bright background (such as metal reflective surface) can still maintain high reliability, becoming the ideal choice for CNC machine tools, heavy machinery and other fields.

Scenario empowerment: the leap from manufacturing to smart manufacturing

- Automotive manufacturing: accurately detect dark tires, reflective frames and other parts to improve assembly line efficiency;

- CNC machining: identifying tiny parts and complex contours to guarantee the consistency of precision machining;

- Packaging machinery: high-speed sorting of multi-colored goods, adapting to the hygiene requirements of the food and pharmaceutical industries;

- Electronic assembly: dealing with PCB board hollow structure, chip surface bump detection, reducing the defect rate.

Why choose the FJN10 laser sensor?

As an innovator in the field of industrial sensing, FUVEI Electronics is always oriented to customer needs:

Multiple output modes: NPN/PNP with different output models can be selected according to the needs;

Long-life design: the stability of laser light source far exceeds that of ordinary LEDs, reducing maintenance costs;

One-stop service: providing customized testing solutions and full-cycle technical support.

In the era of Industry 4.0, intelligent upgrading cannot be separated from the support of reliable sensors. FJN10 series laser sensors have become the “sensing pioneers” in the fields of machinery and equipment, automobile manufacturing, CNC machining and so on, thanks to their accuracy, efficiency and durability. Whether it is to cope with the complex detection environment or the pursuit of ultimate efficiency, it can help enterprises break through bottlenecks with technological innovation and move towards a new height of intelligent manufacturing.