Laser displacement sensor is a commonly used non-contact measuring instrument, mainly for the measurement of length, distance, vibration, thickness, flatness and other physical quantities. Laser displacement sensor has the advantages of accurate measurement, wide measurement range, easy maintenance, strong durability, etc., and is widely used in many industries.

So what factors should be considered when using a laser displacement sensor? Let's take a look at it.

Point one: About the environmental impact

One of the reasons for measurement instability: ambient light or random reflection of stray light. When the receiver receives ambient light or stray light, the measured waveform and the waveform of the interference light are combined, resulting in a deviation of the measurement results. In addition, the temperature of the sensor will also affect the change of the measured value.

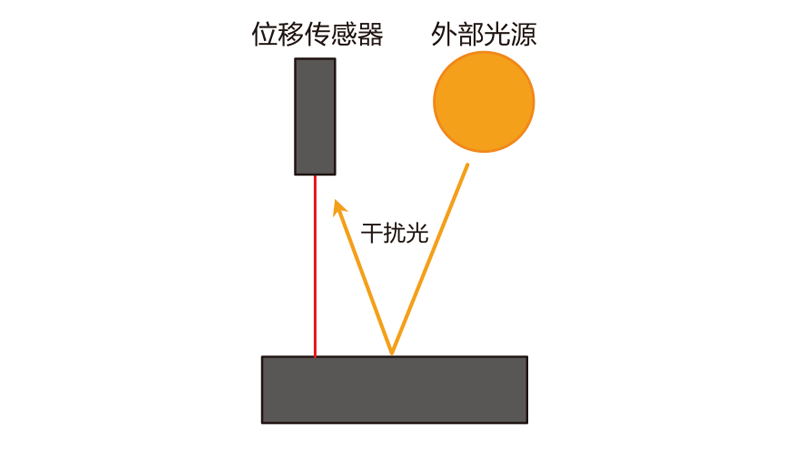

1, the impact of ambient light · chaotic reflection of light

(Ambient light)

Environment simply refers to the presence of strong light in the external environment. For example, it can be affected by strong sunlight. In this case, the interference of ambient light can be avoided by shielding.

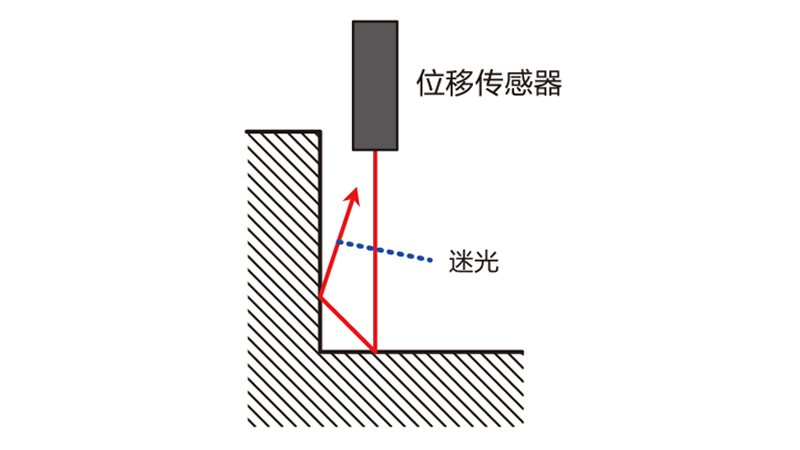

(Stray light)

Random reflection refers to the interference of light reflected to the receiver by rough surfaces or surrounding walls. In this case, the interference of the luminescence can be improved by adjusting the mounting method of the sensor.

2. About temperature change

(Temperature characteristics)

When the temperature of the sensor changes, the measured value will change with the change, usually in [soil 0.01%F.S./℃] to express this characteristic, which is the so-called temperature drift.

This parameter is clearly marked in the product specification table. Therefore, please confirm whether the parameter meets the demand when selecting the product.

(Initial drift)

When the sensor is just switched on, the internal temperature of the sensor continues to rise, and the measured value will continue to change during this period. Therefore, when using the displacement sensor, please confirm the preheating time of the sensor in advance, and then measure after preheating.

Point two: About the light waveform

Due to the function of the built-in feedback loop of the laser displacement sensor to monitor the amount of light received in real time and automatically adjust to the best amount of light received, it is generally not necessary to confirm its light waveform. However, in the following cases, it is necessary to confirm its light waveform, and it can be improved by adjusting the installation method.

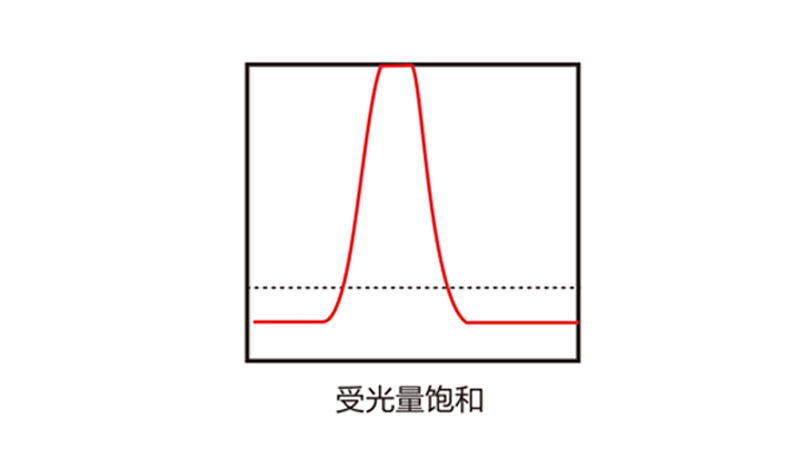

1. When measuring metal objects with high reflectivity

When measuring objects with high reflectance (such as glossy metals, etc.), the amount of light received is easily saturated when the laser intensity is strong. When the received light is saturated by viewing the received light waveform, the laser intensity value can be reduced, or the installation method of the sensor can be adjusted to reduce the received light value.

2, when measuring black detection material

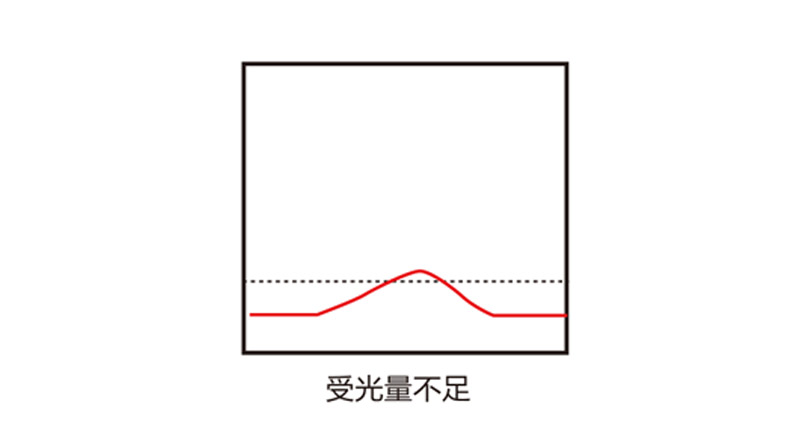

When the sampling period is fast, the sampling time is short, resulting in less light received. Therefore, when measuring objects with low reflectivity (such as black rubber, etc.), or high-speed measurements, it is necessary to view the light waveform to confirm whether there is sufficient light.

3. When measuring transparent objects

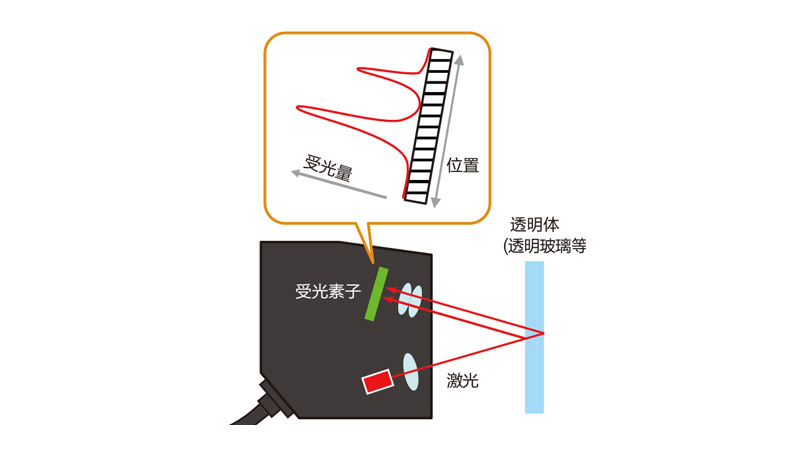

When measuring transparent bodies, the sensor must be mounted at an Angle so that the receiver can receive the reflected light that is positively reflected. Since the margin of the tilt Angle is 2 to 5°(depending on the model), it is possible to verify the stability of the measurement by looking at the received light waveform. When measuring the thickness of a transparent body, as shown in the figure below, the sensor receiver can normally receive the reflected light on the surface and back.

Fuwei Electronics is a comprehensive high-tech enterprise focusing on industrial sensors and deep learning technology, and is also an excellent supplier of industrial automation products in China. The laser displacement sensor developed and produced by the majority of customers and friends alike praise and love. Laser displacement microphone types are rich, can meet the different application scenarios of customers, widely used in universities and research institutions, automotive industry, machinery manufacturing industry, aviation and military industry, metallurgy and material industry accurate measurement and detection, to help enterprises optimize the production process, improve product quality and performance.