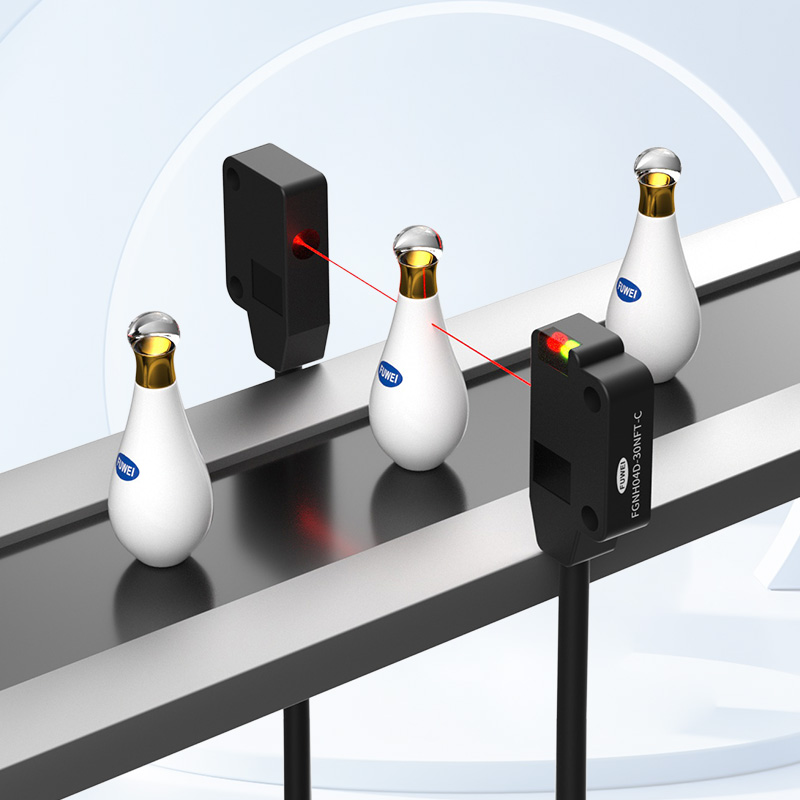

At a time when intelligent manufacturing is demanding the utmost in precision and efficiency, the FGNH04 series photoelectric switch from Foway Electronics has become the “nanoscale sentinel” in the field of industrial automation, with a full-area detecting capability of 2-500mm and a response speed of 1ms. This ultra-thin sensor with a thickness of only 6.5mm is rewriting the technical boundaries of photoelectric detection by virtue of its full-scene adaptability and military-grade durability.

Millimeter Precision: Full Control from Hair to Giant Objects

FGNH04's “diffuse reflection detection black technology” breaks the detection blind spot of traditional sensors:

2mm ultra-close detection: accurately capturing the placement position of micro-electronic components, and successfully recognizing the positional deviation of 0.3mm in the connector detection of 3C products;

500mm long-distance detection: no need for reflectors to penetrate the complex production line environment, in the automotive assembly plant material pallet inspection, stable identification of 3 meters away from the multi-layer stacked workpieces.

Its ф1mm minimum detection capability, the industry for the first time to achieve the diameter of less than a hair (human hair about 70μm) of the opaque objects of reliable detection, in the lithium electrode sheet defect detection scenarios, the leakage rate compared with the traditional equipment to reduce 92%.

Second, millisecond response: the “nerve endings” of the high-speed production line

When the speed of the production line is increased to 3m/s, the 1ms response time of FGNH04 shows a crushing advantage - it can complete 1000 inspections per second, ensuring zero leakage of workpieces in high-speed movement (such as high-speed sorting of express parcels and speeding PCB boards). With NPN/PNP different output models (NO/NC optional), it can be seamlessly connected to various types of PLC and control systems.

Full-scene adaptation: “versatile” in the industrial environment.

Various detection types: Diffuse reflection mode adapts to the scene without reflective plate, and the opposite mode realizes 500mm ultra-long distance detection, and mode switching can be completed through the knob, which is compatible with 98% of industrial inspection scenes;

Ultra-thin body design: 6.5mm thickness can be embedded in narrow spaces (e.g. injection mold gaps, robot joint recesses), increasing installation flexibility by 40%;

IP66 protection level: in the dusty (dust concentration ≤1000mg/m³), humid (humidity 95% RH) harsh environment, continuous operation of 20,000 hours without failure, compared with similar products to extend the life expectancy by 3 times.

Intelligent design: redefine “ready to use”.

Anti-interference filtering algorithm: Built-in intelligent chip filters ambient light (100000lux bright light) and electromagnetic interference, which improves the detection stability by 50% in the welding workshop and other strong light source scenarios.

In the intelligent production line of Industry 4.0, for every 1% increase in detection accuracy, the yield rate can be increased by 0.8% - this is exactly where the value of FGNH04 background suppression photoelectric switch lies. With 15 years of sensor R&D experience, FGNH04 integrates “millimeter-level detection” and “full-scene adaptation” into this 6.5mm-thick industrial device, providing “smaller size, stronger performance, and lower cost” detection solutions for smart manufacturing.