In the field of intelligent manufacturing, photoelectric sensors as the core detection element, its performance directly affects the stability and efficiency of the production line.FGNH04-30NF-B series photoelectric sensors become the ideal choice for automation scenarios due to its compact size, sensitive sensing, stability and durability, and other characteristics.

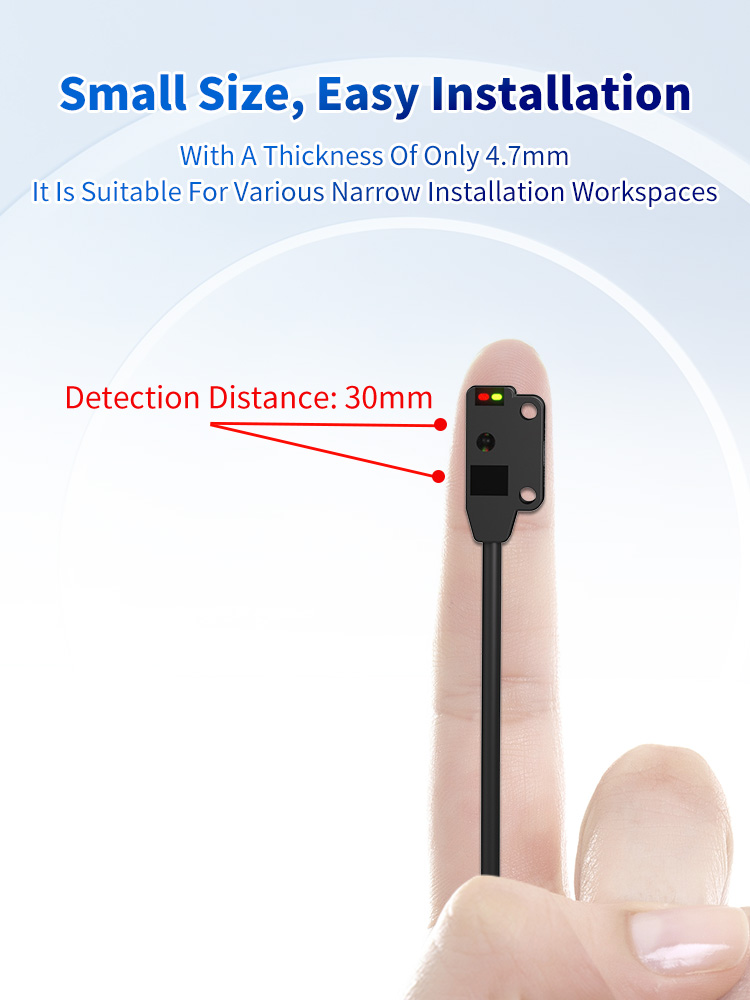

Compact design and flexible installation

FGNH04-30NF-B series adopts standard M3 size mounting holes, and the overall volume is only 20×31×11mm, which can be easily embedded into small spaces. This design is particularly suitable for precision equipment or dense deployment of multiple sensors, such as the inspection of miniature parts in electronic component assembly lines. Through the standardized interface, the installation time is 40% shorter than traditional sensors, significantly reducing the complexity and cost of equipment transformation.

Second, accurate detection, intelligent adaptation

Sensor equipped with visible red light point positioning technology, debugging users can intuitively observe the position of the beam, quickly complete the target alignment. Its built-in new imported electronic components (such as high-precision photodiode and signal processor), with adaptive algorithms, real-time monitoring of the amount of light and automatically adjust the sensitivity. This intelligent mechanism allows the sensor to effectively reduce the interference of the workpiece color, tilt, for example, in the detection of black plastic parts, can still maintain the detection accuracy of ± 0.5mm, while the traditional sensors may be due to the difference in reflectivity leads to misjudgment.

Stable, reliable and durable

Thanks to the military-grade materials and technology, FGNH04-30NF-B series can still work stably in a wide temperature range from - 25℃ to 70℃. Its core components are imported chips, and its life span can reach more than 50,000 hours, which is 30% longer than that of similar products. In practice, a food packaging line using the sensor for 18 months of continuous operation, the failure rate is less than 0.3%, significantly reducing the cost of downtime maintenance.

Fourth, transparent detection, breakthrough

For the detection of transparent objects, the series adopts coaxial optical design and circular polarization technology. When detecting transparent test tubes or glass containers, the sensor can accurately identify the presence and location of the object by analyzing the change in the polarization state of the refracted light, avoiding false triggering due to specular reflection. In a medical device production line, the sensor has successfully realized stable detection of 0.1mm thick transparent film with 99.9% accuracy.

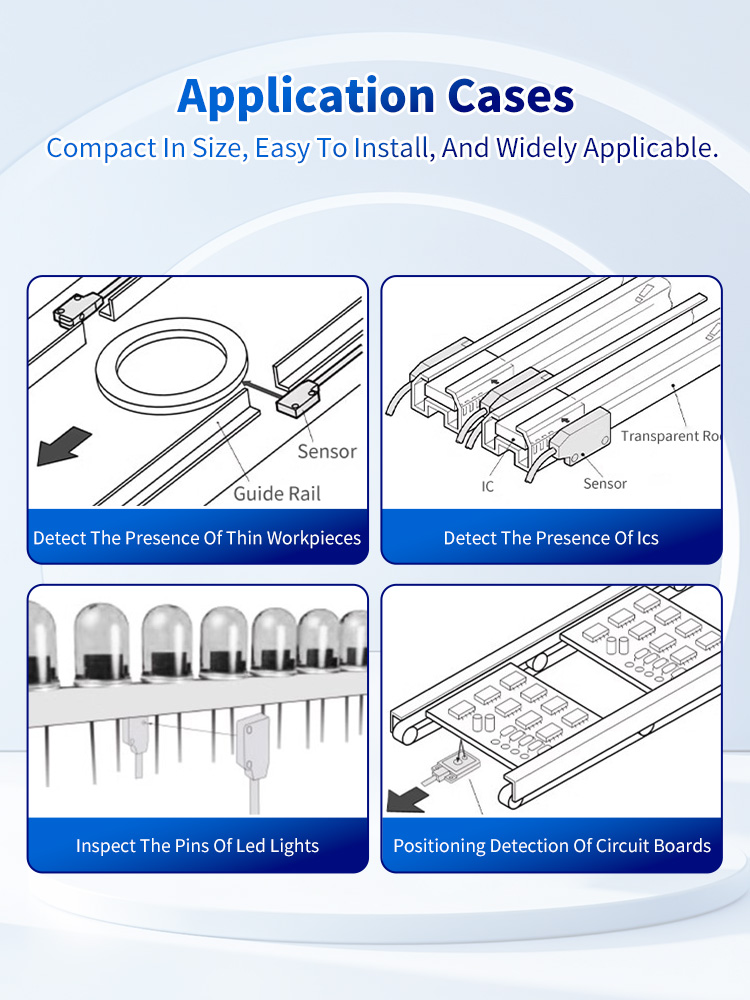

V. Scene Adaptation, Efficient Empowerment

FGNH04-30NF-B series are widely used in automated production lines, logistics sorting, medical equipment and other fields:

Industrial manufacturing: in automotive parts assembly, real-time monitoring of parts in place to ensure assembly accuracy;

Packaging industry: detecting skewed or missing labels on medicine bottles to prevent inferior products from entering the market;

Intelligent warehousing: identifying the position of transparent plastic boxes to optimize the AGV handling path.

Conclusion

FGNH04-30NF-B series photoelectric sensors redefine the standard of industrial inspection with the core advantages of miniaturized design, intelligent detection and high reliability. Whether it is accurate measurement in complex environments or efficient identification of transparent objects, it can provide stable and economical solutions for enterprises and help intelligent manufacturing upgrade.