Under the wave of Industry 4.0, high-precision, non-contact measurement technology has become the “core engine” of intelligent manufacturing, and CCD wire diameter measurement sensors have become a key tool in the field of precision manufacturing due to their excellent real-time performance, anti-interference ability and micron-level accuracy. The FLM-50-RS485 laser distance measurement sensor launched by FWE takes 2ms fast response and 10μm repeatability as its core advantages, and combines with innovative design to provide efficient and stable measurement solutions for industrial scenarios.

Technological innovation: double breakthrough in speed and accuracy

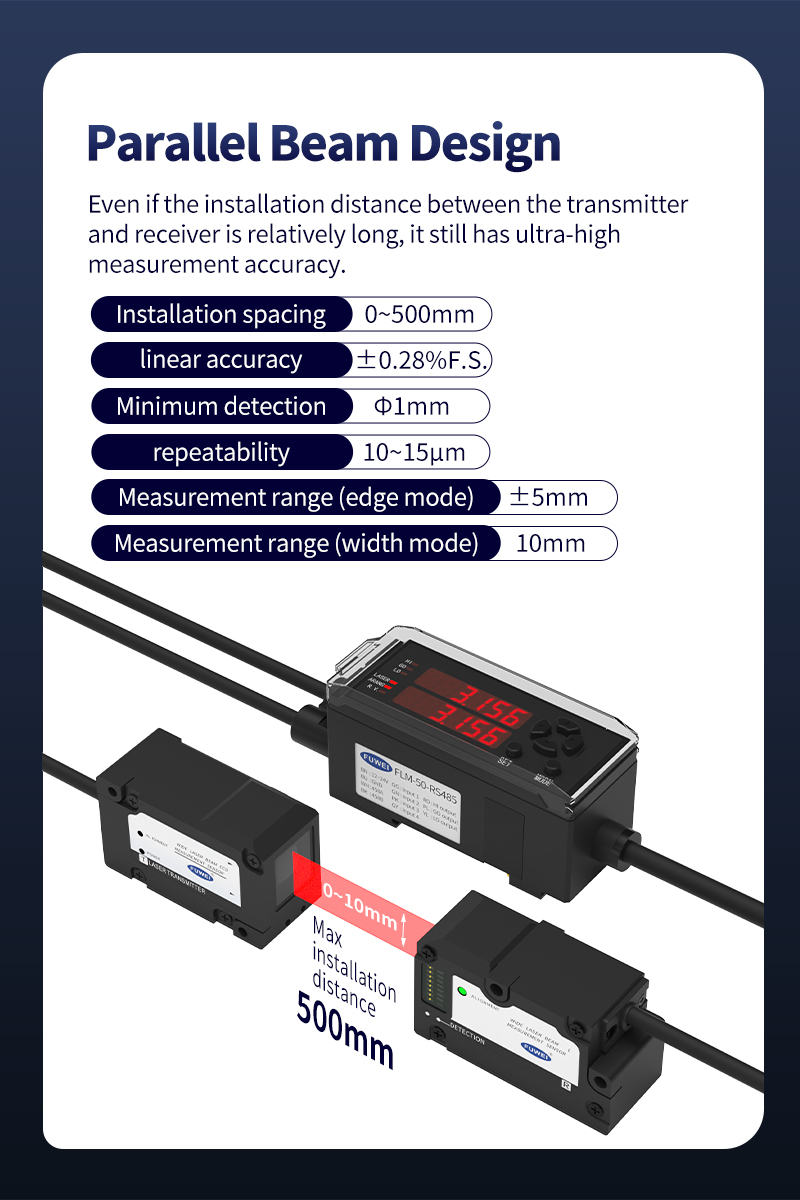

Traditional measuring equipment often affects productivity due to delayed response or lack of precision, while CCD wire diameter measurement sensors realize “instantaneous capture” through the deep integration of optics and algorithms. The FLM-50-RS485 from FWE adopts high-precision CMOS sensing technology with self-developed algorithmic model, which can complete data acquisition and analysis within 2ms, and the response speed is more than 50% higher than that of traditional solutions. Its 10μm-level repeatability ensures data stability even in high-speed dynamic scenarios (e.g. cable extrusion OD measurement), avoiding errors caused by jitter or temperature drift.

In addition, the sensor adopts a uniform light spot design, with a spot size as low as 14*12mm and IP67 protection rating.

Scenario Enabling: Multi-field Applications

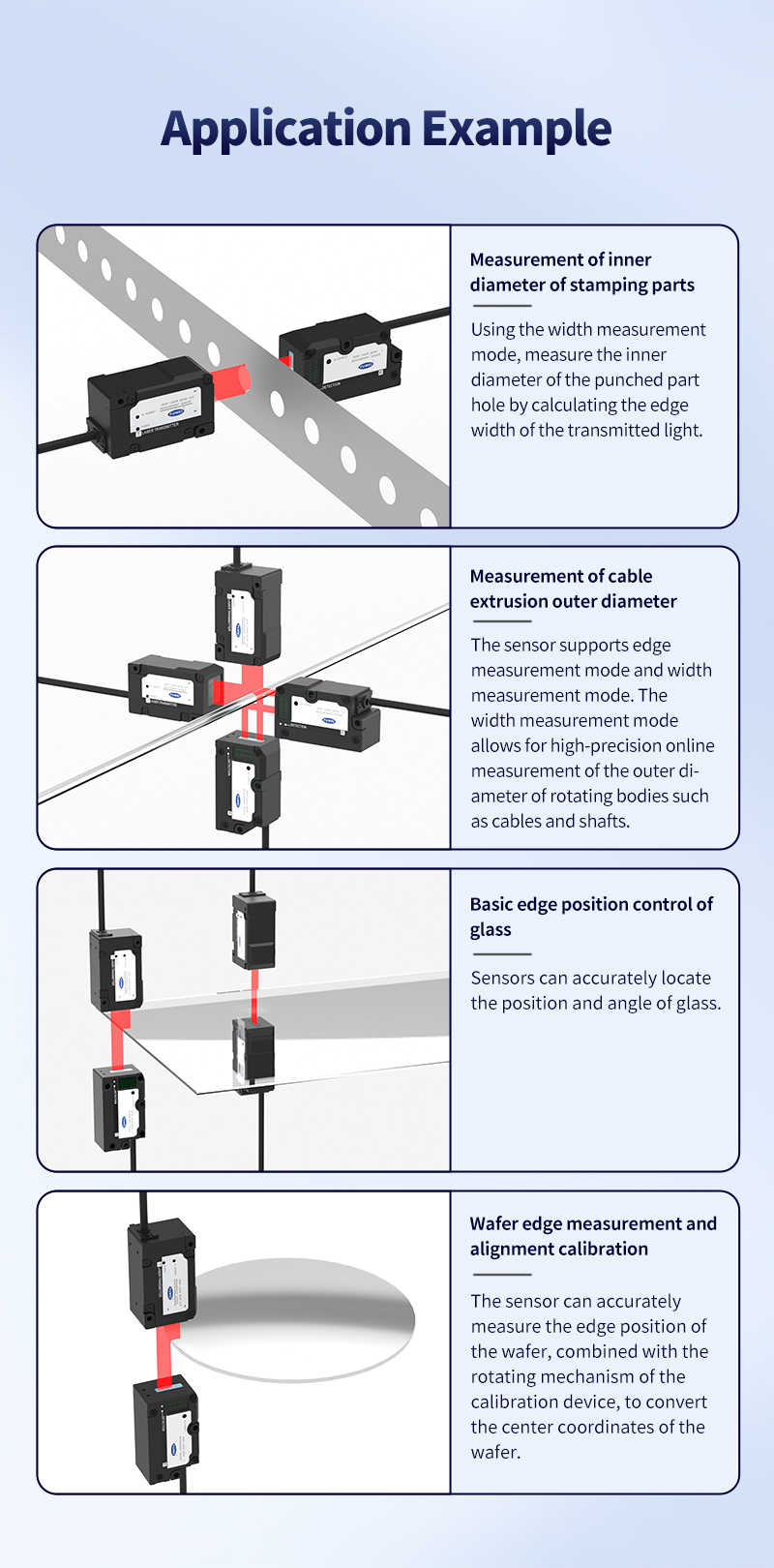

The flexibility of CCD wire diameter measurement sensors makes them easy to use in complex industrial scenarios:

Stamping parts inside diameter measurement: traditional contact measurement is easy to damage the surface of the workpiece, FLM-50-RS485 through non-contact laser scanning, combined with RS485 communication real-time feedback data, the accuracy of up to ± 0.28% F.S., perfectly adapted to the needs of high-precision mold inspection.

Cable extrusion O.D. monitoring: In the cable production line, the sensor dynamically captures the O.D. change with 500Hz sampling frequency, and seamlessly connects with PLC with ModBus protocol to realize closed-loop control and reduce material waste.

Cylinder gap calibration: With dual-channel switching output, the sensor can trigger the deskew system in real time to ensure the uniformity of cylinder gap in textile and printing industries, avoiding the increase of defective rate caused by mechanical wear.

Wafer edge positioning and winding deskew: For semiconductor manufacturing, the miniaturized design of the sensor can be embedded in narrow spaces, and the 14*12mm spot accurately identifies the wafer contour.

CCD wire diameter measurement sensor is not only a measurement tool, but also the core pivot point for improving quality and efficiency. With micron-level precision, millisecond response and scenario-based adaptability, FLM-50-RS485 is helping automotive manufacturing, new energy, semiconductor and other industries to break through the precision bottleneck.