In high-precision fields such as precision manufacturing, semiconductor packaging and automotive inspection, the detection capability of laser displacement sensors directly determines product quality and production efficiency. In the face of traditional sensors with limited detection range, poor environmental adaptability, short life and other pain points, Fu Wei Intelligence launched the revolutionary FSD23 series laser displacement sensors, with 10-250mm ultra-wide range, ±0.1% F.S. linear accuracy and IP67-level protection of the three core advantages, to redefine the performance boundaries of the industrial inspection equipment.

A dual breakthrough in range and accuracy: from “single scene” to “full coverage”.

Traditional sensors are often forced to customize multiple models of equipment due to narrow range (such as fixed 30mm detection range), resulting in a surge in production line deployment costs. FSD23 series laser displacement sensors, however, realize a continuously adjustable detection range of 10mm to 250mm through self-developed optical module dynamic focusing technology, which is suitable for all scenarios ranging from micron chip soldering joints to automotive sheet metal gaps.

In cell phone glass inspection, FSD23 can switch inspection modes within 0.1 seconds:

Ultra close range mode (10-50mm): recognizes glass scratches at 0.01mm level;

Medium-long distance mode (50-150mm): measuring curvature deviation of curved screen;

Long distance mode (150-250mm): high-speed scanning of the whole machine assembly accuracy.

With ± 0.1% F.S. linear accuracy, the detection efficiency is increased by 300% compared with traditional sensors, and the false judgment rate is reduced to 0.005%.

Second, extreme environmental adaptability: IP67 protection + aluminum alloy shell of industrial-grade guarding

Industrial site of water mist, oil, metal dust is called the laser displacement sensor “invisible killer”. An automotive welding workshop measured data show that the failure rate of ordinary sensors in the oil mist environment is as high as 35%, while the FSD23 series with three major protection design to achieve 99.9% trouble-free operation:

IP67 waterproof and dustproof: the fully sealed aluminum alloy shell can withstand 1 meter water depth immersion for 30 minutes, dust permeability<0.01%;

Anti-interference optical system: through the adaptive light filtering algorithm, eliminating welding arc light, environmental stray light interference, in 15000lux strong light still maintain accuracy;

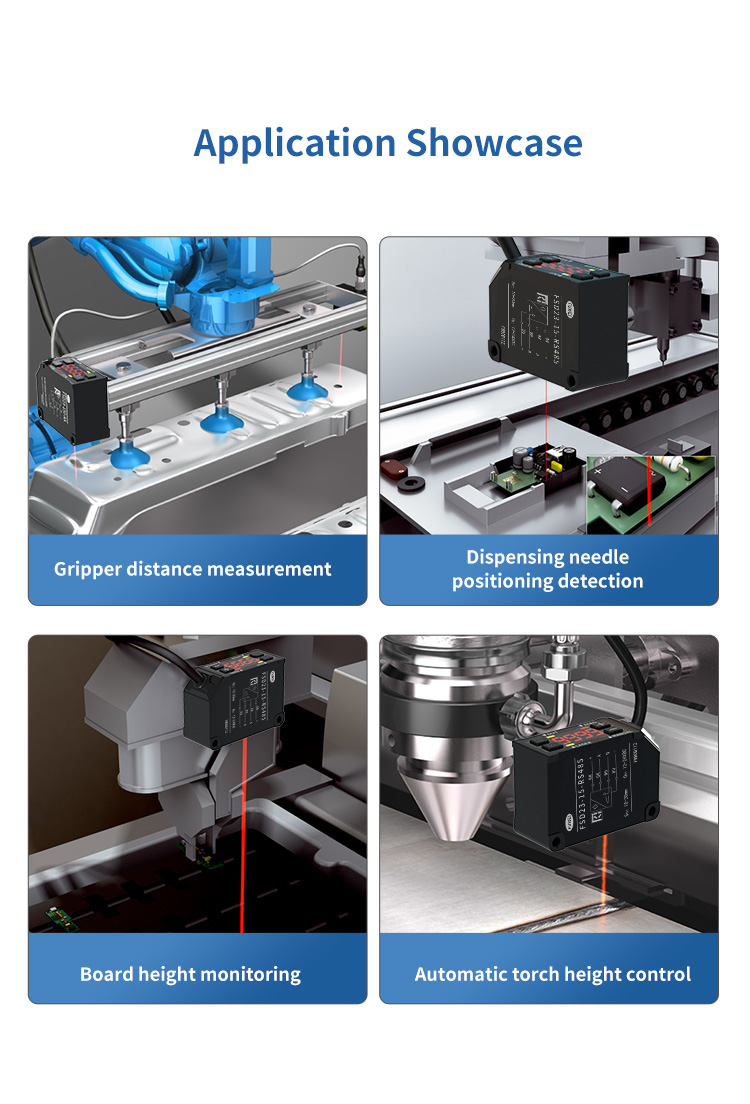

Third, the scene revolution: unlocking four high-value areas

Semiconductor packaging

Detecting wafer warpage and solder ball height with an accuracy of ±0.5μm, reducing the cost of imported equipment by 60%.

Automobile Manufacturing

In body-in-white gap surface difference detection, the 250mm range covers the full dimensional measurement of the door and hood, and the beat time is shortened to 8 seconds/unit.

3C electronics

Curved screen curvature detection accuracy of ±0.01mm, compatible with the folding screen opening and closing angle of 10-180 ° full dynamic monitoring.

Photovoltaic industry

Silicon wafer cutting thickness online inspection, 0.1ms level response speed to achieve 100% full inspection, debris rate down 90%.

In the future, as the demand for micron-level manufacturing explodes, laser displacement sensors will evolve in the direction of smarter and more miniaturized. Choose FSD23 series, let every laser beam become your strategic weapon to win the precision manufacturing track!