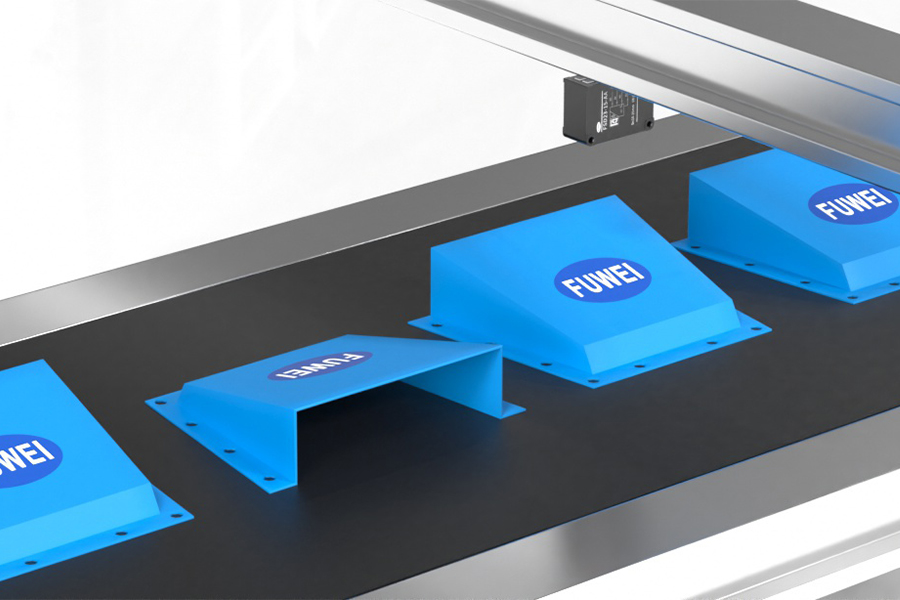

Height measurement of molds is critical to ensure product accuracy and quality. Traditional measurement methods are often limited by precision and efficiency, and are difficult to meet the needs of modern mold manufacturing. The application of Fuwei laser displacement sensor provides a brand new solution for the accurate measurement of mold height. Its laser measurement technology has the characteristics of non-contact, high precision, fast response, etc., which can realize the accurate measurement of mold height and effectively improve the efficiency and quality of mold manufacturing.

The following is to share the application case of laser displacement sensor precision thickness measurement in the mold production industry~

Detection needs:

The workpiece is a trapezoidal shape with a slight slope, behind the flow line is a servo handling mechanism, if the workpiece is put on the opposite side of the high and low sides, the back of the material plastic tray can not be put in smoothly, so here we need to choose a displacement sensor that can measure the thickness to measure the high and low sides of the workpiece, to confirm that the workpiece has been put on the opposite side.

Difficulty dissection:

1、Fast streamline transfer speed

2、Workpiece may have up and down jumping action

Solution:

Laser triangulation principle with powerful software algorithms in order to achieve high stability and contactless accurate measurement;

Linearity up to ±0.1% F.S for contactless, wear-free precision measurement.

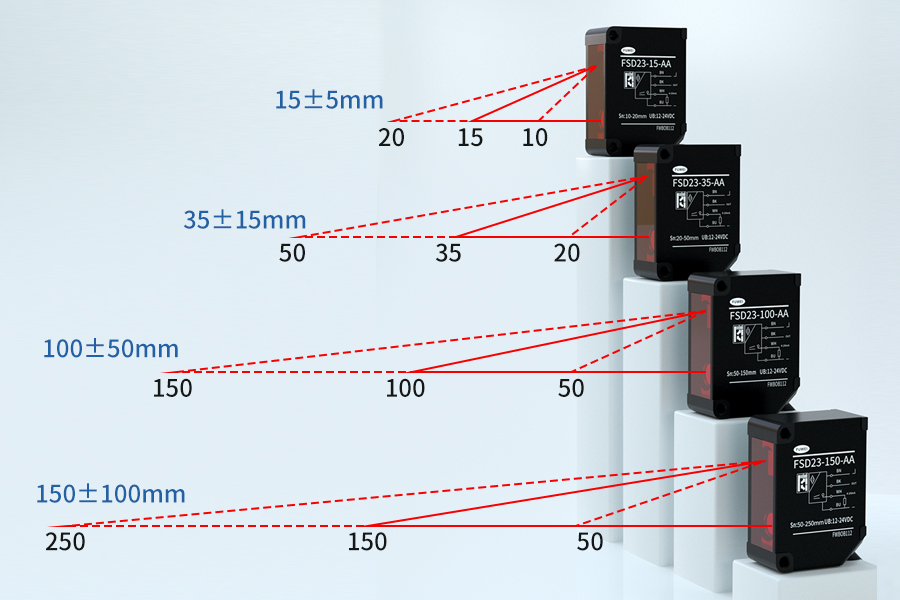

Detection distance (15/35/100/150mm), even if there is some deviation in the position of the streamline will not affect the detection effect.

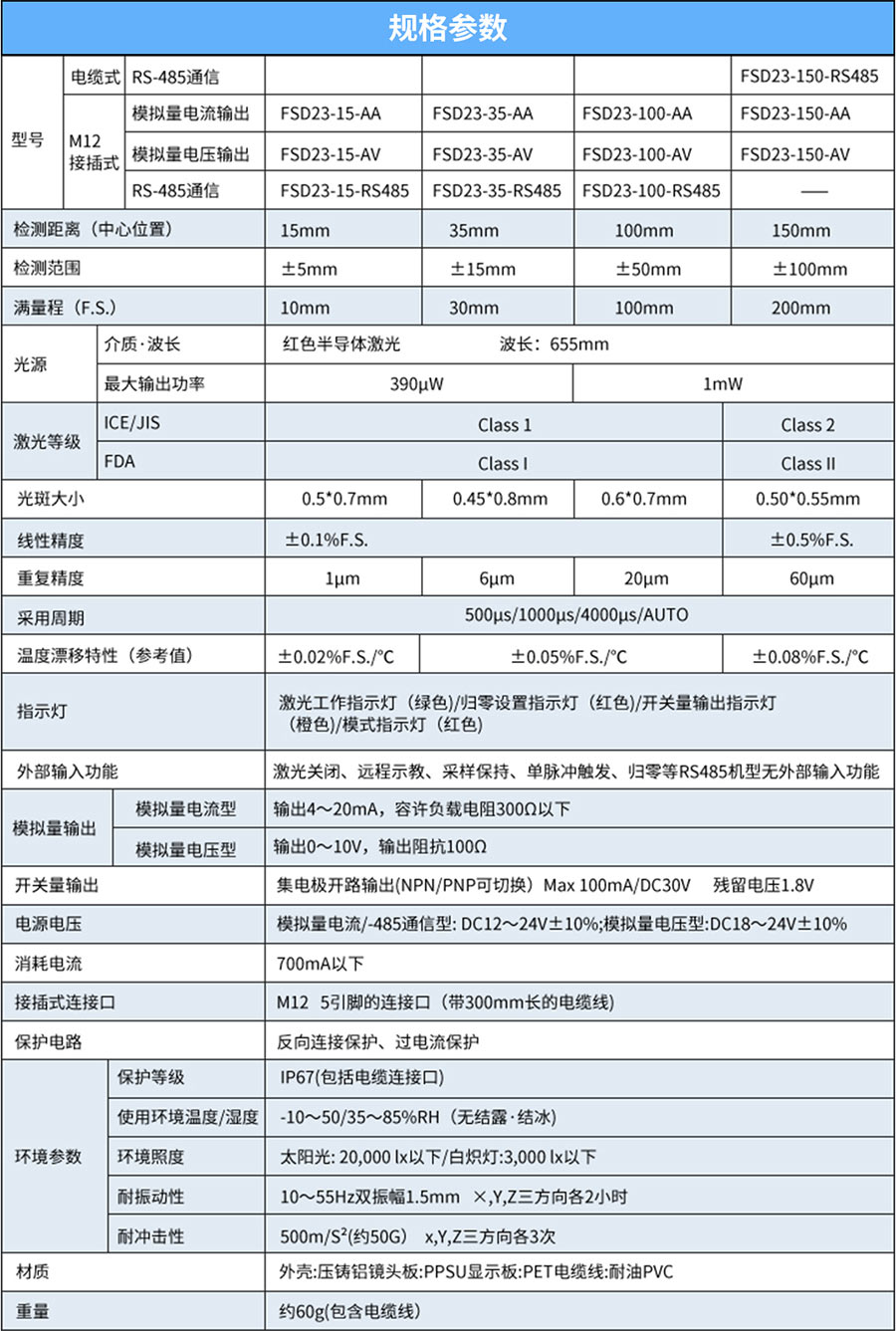

Product Parameters :